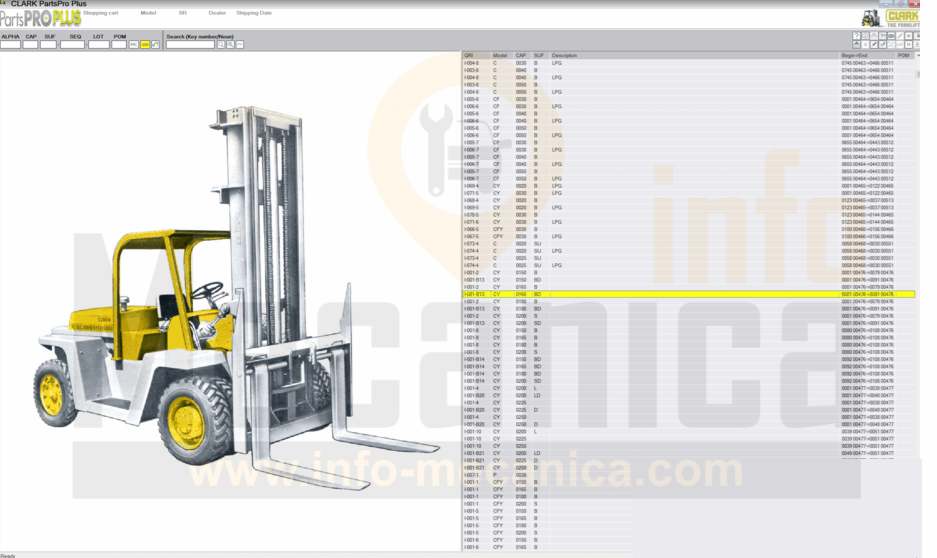

One Stop Training – A Simple Way to Get Your Forklift Licence. One Stop Training is the top choice for people wanting to get a forklift licence in South East Queensland. Whether you are looking for a forklift licence in Brisbane or a forklift licence on the Gold Coast, we’ve got you covered. Create An Optimized & Intelligent Operation. Our intelligent warehouse technology solutions, from telematics to automation to our new operator learning tool, the virtual reality simulator, are designed to help you run better and manage smarter, in all areas of your operations. Here is our extensive Clark forklift service manual library (PDF formats) that includes the forklift repair and parts documentation and service instructions that you need for your warehouse or forklift-supported operation. Also access below the Clark forklift parts manual you need. Johnston Equipment offers Raymond Forklifts and Raymond lift trucks for sale, rent or lease, as well as offering Forklift Operator Certification, lift truck parts and service, as well as a myriad of other brands such as Nilfisk, BT, Bravi & Motrec.

| ||

Industrial workplaces have come to rely on forklift trucks for their ability to lift and transport just about any load around the plant. The power of forklifts makes them indispensable, but also dangerous. Often when employees grow accustomed to using forklifts they tend to stop thinking of them as a safety hazard, and forget or neglect to follow some important operating and

maintenance procedures. When forklift injuries occur, they're usually serious given the tremendous weight of those powerful machines.

Employees must be trained to work safely with forklifts, not just when they're hired but periodically thereafter. Refresher training for the experienced operator is just as important as first-time training for new employees. It's also a good idea for employees to receive basic first aid training in case of injuries.

Forklift Inspection

Although forklifts are designed to perform rugged tasks, each time they are used they can get damaged in any number of ways. That's why inspection is of critical importance. At the start of each shift, perform both a visual inspection of the general condition and cleanliness of the lift truck, as well as an operational check to test its proper functioning. If you notice anything that may affect the normal operation of the forklift, immediately alert your supervisor.

Checklist for Visual Inspection

- floor--clear of objects that could cause an accident

- no obstructions overhead

- note any nearby objects to avoid as you drive away

- fire extinguisher present, and charged

- engine oil level, fuel level, radiator water level (LPG, gas and diesel forklifts)

- battery fully charged and securely in place

- cables for exposed wires

- battery plug connections not loose, worn or dirty

- vent caps not clogged

- electrolyte levels in cells

- hold downs or brackets

- bolts, nuts, guards, chains, or hydraulic hose reels not damaged, missing or loose

- wheels and tires not worn or damaged

- air pressure of pneumatic tires

- forks not bent or cracked

- positioning latches in good working condition

- carriage teeth not broken, chipped or worn

- chain anchor pins not worn, loose or bent

- no damp spots or drips that may indicate a leak

- hoses held securely, not loose, crimped, worn or rubbing

Checklist for Operational Pre-Use Inspection

- horn working and loud enough to be heard in working environment; other warning devices operational

- floor brake: pedal holds, unit stops smoothly

- parking brake: holds against slight acceleration

- deadman seat brake: holds when operator rises from seat

- clutch and gearshift: shifts smoothly with no jumping or jerking

- dash control panel: all lights and gauges operational

- steering: moves smoothly

- lift mechanism: operates smoothly (check by raising forks to maximum height then lowering completely)

- tilt mechanism: moves smoothly, holds (check by tilting mast all the way forward and backward)

- cylinders and hoses: not leaking after above checks

- no unusual sounds

- Permit only qualified people to service and maintain forklift trucks.

Forklift Operation

No one must ride or operate a forklift truck except for a trained forklift operator who is able to maintain control of the forklift and operate it smoothly when stopping, starting, lifting and tilting. The following pages list some important guidelines on forklift safety.

Travelling

Keep your hands, arms, head, feet and legs inside the forklift truck. Travel with forks as low as possible from the floor and tilted back. Obey posted traffic signs. Decrease speed at all corners, sound horn and watch the swing of both the rear of the lift truck and the load. Avoid sudden stops. If the load blocks your vision, travel slowly in reverse. Always look in the direction of travel. Keep an eye out for oil spots, wet spots, loose objects, holes, rough surfaces, people and vehicles on the floor or roadway.

To ensure the safety of others, know the blind spots of the lift truck with and without a load. When anyone crosses the route being travelled, stop the forklift truck. Lower the load to the floor, and wait until passage is clear.

Travelling on an Incline

Keep the forks pointed downhill without a load, and pointed uphill with a load. Do not attempt to turn the lift truck until it's on level ground.

Steering

Support the load by the front wheels and turn with the rear wheels. Do not turn the steering wheel sharply when travelling fast. If the lift truck is overloaded, steering will be difficult. Do not exceed load limits, and do not add a counterweight as an attempt to improve steering.

Loading

It's important to know the recommended load limit of the forklift (shown on the data plate) and the capacity of the fork, and to never exceed these limits.

Position the load according to the recommended load centre. Do not add extra weight to counterbalance an overload. Keep the load close to the front wheels to keep the lift truck stable.

When inserting the fork, keep the mast of the forklift in an upright position before inserting the fork into a pallet. Level the fork before inserting it.

Raising the Load

Do not raise or lower the fork unless the lift truck is stopped and braked. Avoid lifting a load that extends above the load backrest if there's any risk of the load, or part of it, sliding back toward the operator. Check for adequate overhead clearance before raising a load, and maintain a safe working distance from overhead power lines. Lift the load straight up, then tilt back slightly. Watch that the load doesn't catch on adjacent loads or obstructions. Don't back up until the forks are free.

When a load is raised, the lift truck is less stable. The operator must stay on the forklift when the load is in a raised position. Don't allow anyone to stand or walk under the elevated part of the forklift, whether it's loaded or unloaded.

Handling Pallets

Ensure that forks are level and high enough to go into the pallet, and that they go all the way under the load. Forks must be the proper width to provide even weight distribution.

Avoid trying to move or adjust any part of the load, the forklift or the surroundings when on the forklift. Do not use pallets elevated by forklifts as an improvised working platform.

Parking

Park only in an approved location. When leaving the lift truck unattended, secure it by setting the brakes, lowering the forks or load to the floor, neutralizing the controls, and turning off the motor switch. Disconnect the battery or go through propane shut-down procedures.

Loading or Unloading Straight Trucks, Tractor Trailers, and Railway Cars

Preparing the vehicle being loaded or unloaded

Set the vehicle's brakes, and chock the wheels. Install fixed jacks to support a semi-trailer that is not coupled to a tractor to prevent it from upending. Post signs warning people not to move a vehicle. Check that the height of the vehicle's entrance door clears the forklift height by at least 5 cm (2 in). Make sure floors can support the combined weight of the forklift and the load.

Inspect the vehicle's interior for trash, loose objects and obstructions, holes in the floor, and poor lighting. Install nonslip material in any area that could be a slipping hazard.

Ensure that docks and dockplates are clear of obstructions and not oily or wet. Naruto gekitou ninja taisen special wii iso download.

Loading or unloading the vehicle

Stay clear of edges of docks, rail cars or ramps. Have edges clearly marked.

Do not tow or push railway cars or trucks with a forklift. Do not operate forklifts inside vehicles for long periods without ventilation. Make sure that the dockplate is properly secured and can support the load (load weight should be clearly marked). Drive carefully and slowly over the plate. Do not spin the wheels.

Loading railway cars

Cross the railway track on a diagonal. Set handbrakes, wheel blocks and derailer before entering a railway car. Do not park a forklift within three meters of railway tracks. Do not open railway car doors with forklift forks.

Entering an Elevator with a Forklift Truck

Forklift Service Near Me

Do not enter any elevator unless specifically authorized to do so. Before entering, ensure that the forklift plus load weight does not the exceed the elevator capacity. Approach the elevator slowly. Stop at a safe distance from the elevator gate, then enter squarely.

Neutralize the forklift controls. Shut off the motor and apply the brakes.

When working on or near a forklift, stay alert and prepare for the unexpected. Immediately report any collisions, damage or near-misses to a supervisor.

Forklift Repair Company Near Me

For more information on forklift safety, contact the Inquiries Service at the Canadian Centre for Occupational Health and Safety at 1-800-668-4284 or help yourself to the information in OSH Answers.